These are essential to establish a digital ecosystem that enables the convergence of virtual and real world data for the truly autonomous factory. Hexagon is driving the journey toward autonomous intelligence by enabling manufacturers to converge functions with core technologies like artificial intelligence (AI), edge computing, and mobile applications. Advancements in automation and smart factory solutions have given manufacturers the confidence to think seriously about autonomous enterprises, where systems draw upon multiple sources of data unaided and make autonomous smart decisions. But increasingly when people talk about factory automation, the conversation isn’t just about reducing manual intervention-it’s about lights-out manufacturing. Obviously the world’s technological capabilities have come a long way in just the last couple of decades the levels of efficiency and connectivity we can achieve through automated solutions are unprecedented. ME: What’s new in factory automation, and how is Hexagon addressing it?īrian Shepherd: Hexagon’s core vision is to move processes beyond automation to autonomy.

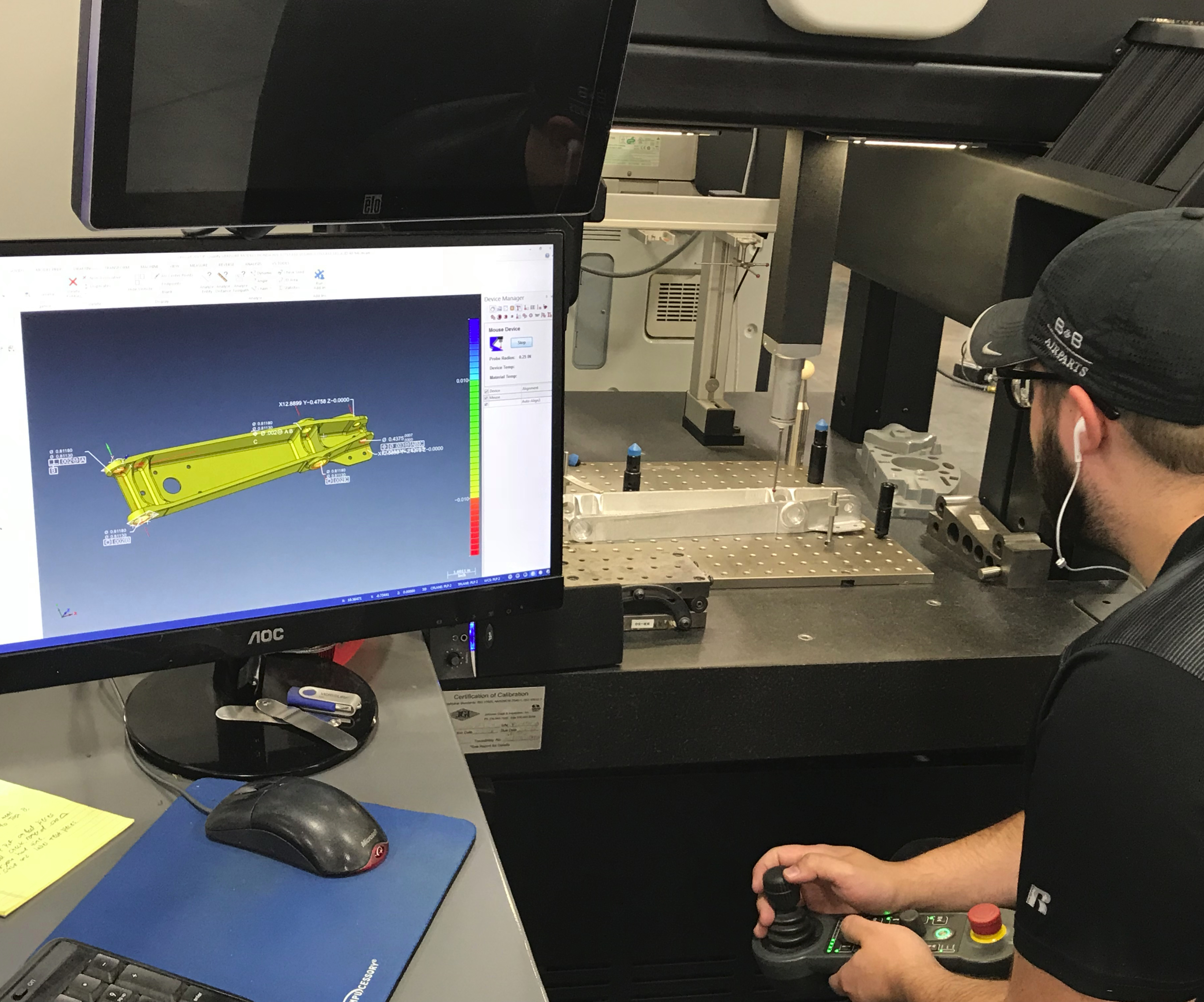

Ultimately, data sharing to drive feedback loops is essential to increase factory automation and productivity. Processes are improved automatically while the machines are in operation, with no requirement for manual intervention. We can automatically make program corrections in the CNC to keep production on spec, for example if the tool is wearing. We use statistical process control software to identify trends in the measured data from the machined parts. That’s why we’re really focused on giving customers a holistic view of their manufacturing data in real time, so smart decision-making can drive productivity.įor example, we’ve been demonstrating the effectiveness of this approach in closed-loop manufacturing cells, where a part is machined before being automatically moved to a coordinate measuring machine for inspection. Quality data can deliver valuable insights into production processes, and vice versa. As we continue to expand our offerings across these areas, we’re developing greater synergies between systems and software across these traditionally siloed workflows. Steve Graham: We have a very broad portfolio in the manufacturing space, with solutions spanning design and engineering, production, through to metrology. Hexagon is focused on giving customers a holistic view of manufacturing data in real time. Manufacturing Engineering: Describe Hexagon’s latest moves in factory automation, including unifying its metrology software with its CAD/CAM and other manufacturing software.

0 kommentar(er)

0 kommentar(er)